Prototype response system

Customers come to us for a wide variety of reasons: “I want to fit functions into a limited space… I want to draft an image… Nothing else worked for me… I’m concerned about durability… I want to try out self-manufacturing springs… I need you to respond promptly to problems with defects/design changes…”. At the Koriyama Prototype Center, we are equipped with five kinds of NC multi-forming machines and our highly qualified technical staff will meet our customers’ demands. In addition, through collaboration with the Kashiwazaki Plant and overseas plants, we will make the process from trial production to manufacturing smoother.

Koriyama Prototype Center

Features

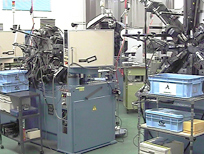

1. Specialized facilities for prototype production

The prototype center is equipped with five types of NC multi-forming machines, for wire diameters is from 0.05 to 2.0 mm, with the capability to handle incredibly small springs with wire diameters down to 15 μm. Capacity is available for push springs up to wire diameter φ0.015/O.D. φ0.075, for pull springs up to wire diameter φ0.08/O.D. φ0.8, and torsion springs up to wire diameter φ0.05/O.D. φ0.5. Since we can also handle automatic machining from the time of trial manufacture, we can also manufacture prototypes in large quantities.

2. Staff with advanced technological capabilities

Our staff comprises specialists with highly technical capabilities who have experienced the operation of NC multi-forming machines for more than 15 years. In addition to checking drawing dimensions, loads, durability, etc. beforehand, we also draw them from the actual product and the partner parts, and design and draw them in accordance with the required loads and torque. We are also engaged in the development of ADVANEX’s original attachments for complex requests, such as those that allow a single spring to have more than one function.

3. Production collaboration both in Japan and overseas

Everyone is familiar with the facilities and production levels at the Kashiwazaki Plant and overseas plants, which are production bases, so they can examine the feasibility of processing, and find problems in advance. Prototype tools, tool layouts, and programs can be transferred regardless of whether they are in Japan or overseas. Tool layouts, processing conditions, inspection data, etc. at the time of prototyping are stored in a database, so they can be checked from any site. Through such collaboration, we can smoothly perform everything from prototyping to production.

4. Inspection equivalent to that at the production site

It is equipped with the same testing machine as the Kashiwazaki Plant and overseas plants, so it is possible to test and measure load tests, torque tests, two-dimensional measurements, etc. under the same conditions as the production site. Jig design is also performed according to the measurement conditions.

5. Responding to a wide variety of requests from customers

SUS304WPB, SWP-A, B and Ni-plated hard steel wires are always available on customer demand. The NC multi-forming machine does not require complicated dies, so it is even possible to respond on the same day. Depending on the request, we can meet requests for different dimensions and loads while meeting at the factory.

Interview

Interview with Mr. Eito Nagayama of the Koriyama Prototype Center

Movie 1: Facilities, production capacity, and inspection system at the Prototype Centre

Sorry, this video is only available in Japanese.

Facilities and production capacity of the ADVANEX Koriyama Prototype Center that meets various customer needs. Since automatic processing is also possible from the time of trial manufacture, we can also handle prototypes with large quantities. In addition, we have installed inspection instruments equivalent to those at our production bases.

Interview with Mr. Eito Nagayama of the Koriyama Prototype Center

Movie 2: Responding to various customer requests

Sorry, this video is only available in Japanese.

We can meet a variety of requests from clients for reasons such as: need to deliver functions in a limited space, drafting images, dissatisfaction with other companies, worries over springs in use today……. With five types of NC multi-forming machines, same-day support is also possible.

Interview with Mr. Eito Nagayama of the Koriyama Prototype Center

Movie 3: Cooperation between manufacturing sites in Japan and abroad

Sorry, this video is only available in Japanese.

Prototype tools, tool layouts, and programs can be transferred to production sites both in Japan and abroad. Data can also be checked from each production site. In addition, our staff is familiar with each facility and production levels at each site.

DATA

Production facilities

NNC Multi-Forming Machine

Five Types

Testers

Tester load tester

Torque tester

Two-dimensional measurement equipment

* The same testing machine is installed as at the Kashiwazaki and overseas plants

Staff

Four NC machine specialists

Production capacity

Compression springs: Wire diameter Φ0.015/O.D Φ0.075

Extension Springs: Wire diameter Φ0.08/O.D Φ 0.8

Torsion Springs: Wire diameter Φ0.05/O.D Φ0.5

Minimal springs: Down to 15μ

The machine can also handle automatic processing from the time of trial manufacture, and large quantity trial productions.